Reliably produces printed products of stable high quality. AccurioJet KM-1 uses paper conveying technology identical to that in an offset printer to ensure reliable and stable paper handling. In addition, the use of UV ink ensures highly-accurate registration and minimal nozzle clogging to deliver stable image quality.

|

- Paper-conveying technology identical to that used in Offset Printing.

AccurioJet KM-1 incorporates paper-conveying technology identical to that used for offset printers to realise highly reliable and accurate paper conveyance.

|

Feeder Unit

- Sharp Text Quality

Konica Minolta’s original proprietary font edge-processing technology enables the realisation of excellent text quality with sharpness and legibility even for small font sizes.

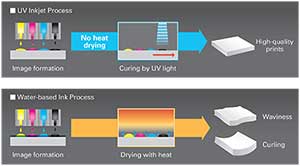

- Greater registration accuracy realised by use of UV ink

The use of UV ink eliminates problems such as waviness or curling commonly occurring during processes such as thermal fixing and drying to achieve superb print quality and highly-accurate registration.

- Stable printing quality.

Because UV ink does not readily dry when exposed to air, problems such as ejection misalignment caused by drying of the ink on nozzle surfaces are minimal compared to other inkjet systems.

- Image quality control by inline sensor

AccurioJet KM-1 is equipped with internal inline sensor that automatically detect and correct image flaws. The inline sensor keep image quality degradation caused by nozzle defects in the inkjet system to a minimum.

|

| Problems such as nozzle misfire and streaks are detected and images automatically corrected by inline sensors. |

|

| Merits of using UV ink. Because processes such as permeation of the paper with solvents and drying are unnecessary, paper waviness is minimised and outstanding registration accuracy and high quality prints are realised. |